The retail industry was beset by uncertainty and unprecedented operational challenge in 2020 as the coronavirus pandemic unfolded across the world. It was a year of sudden lockdowns, store-capacity restrictions, endless sanitization protocols and a fundamental shift in the way customers shop, as more and more buyers opted for online shopping or curbside pickup. For workers, this meant radical changes to their day-to-day responsibilities, and, for many, layoffs both temporary and permanent. But despite a huge drop-off in consumer spending early in 2020, the second half of the year has been a strong one for retail sales, with household spending leading the charge of an industry-wide V-shaped recovery, according to statistics released by the Commerce Department.

This up-and-down (to say the least) year portends even more uncertainty for 2021 and beyond, as the pandemic begins to fade. Will customers return to in-store retail en masse, like it’s 2019 again? Or will many of the shopping habits developed this year linger on into the future? It all leaves employers in a serious bind as they try to square their retail labor costs with the anticipated needs of the consumer. Retailers like Walmart, Kroger and CVS Health all staffed up in major ways during the pandemic, as in-store shopping for pharmacy goods and groceries surged. Meanwhile, Best Buy furloughed more than 50,000 hourly employees at the beginning of the pandemic (many were brought back in July) as it transitioned to a more nimble curbside-pickup model that required fewer in-store associates.

But pandemic or no pandemic, retailers have a set budget for hourly associates (between four and 12 percent of sales, according to an analysis by management consulting firm Korn Ferry), and adjusting that model in the face of shifting in-store challenges and operational requirements is likely the key to ensuring profitability in the short to medium term. “The peak or trough in demand can be so immediate that it’s difficult to plan for that and to have inventory in stock and to get people in the store to help you deliver some of that stuff to the consumer,” Mark Mathews, the National Retail Federation’s vice president of research development and industry analysis, told CNBC. “It very quickly goes from a profitable business to an unprofitable business if you’re not careful.” At this uncertain moment, it’s essential for retailers to optimize their staffing levels to keep retail labor costs in line with consumer demand. Here are three areas where problems can pile up and hours (and dollars) are wasted

1. Inaccurate inventory data

Giving customers what they want, when they want it, is the very backbone of retail. But no matter how advanced a retailer’s inventory management system, it’s seriously hampered if the data fed into is flawed. Bad data can happen for many reasons—from simple input errors to untrackable product exchanges to miscommunications between in-store and online sales channels—but it has long been a one of the major in-store challenges for managers. There’s a snowball effect: inaccurate data leads to more time spent by employees performing store walks and running gap scans, at the expense of high-ROI interactions that directly generate revenue. If the connection sounds tenuous, studies that suggest reducing inaccuracies in inventory data can improve sales by up to eight percent.

The need for accurate, up-to-date inventory information is amplified in an omnichannel sales world increasingly reliant upon curbside pickup and the growing primacy of BOPIS in the customer journey. Accurate real-time product availability means the difference between a customer making a purchase or, with a swipe of the finger or a click of the mouse, moving on to another retailer who has the product ready for sale and pickup. An even larger operational risk: sending employees to look for unavailable products that were erroneously listed as in stock, an all-too-common scenario that means squandered retail labor costs and stinging customer dissatisfaction. It’s the very opposite of giving customers what they want, when they want it.

2. Poor supply chain visibility

Of course, there would be no product on the shelves in the first place without an efficient and reliable supply chain. But with so many moving parts, visibility is crucial for a retailer to anticipate and understand the flow of goods coming to the store. Are you prepared, and properly staffed, for what’s coming? Here again, the importance of reliable inventory data is paramount. Not knowing which products are on the way, or needed to be on the way yesterday, can lead to unpleasant surprises when the delivery truck pulls up. The side effects can ripple throughout the supply chain, and create confusion about where the appropriate product solution can be found, whether it’s at a distribution center, another store, or with a vendor. The result is delays in replenishing inventory, and lost sales opportunities. Historically, it has been a blind spot, with nearly one-third of businesses not analyzing their full supply chain, according to a 2015 survey.

Last-mile logistics are often the most crucial step in the supply chain, but what happens when the product arrives on the loading dock? This is where retail labor costs must be properly optimized, or risk being squandered. Knowing what to expect, and when, is the difference between having the right number of backroom employees to quickly unload the truck and stock the store, or having to call all-hands-on-deck to tackle a larger-than-anticipated delivery, creating in-store challenges like potential gaps in floor staffing, and losing potential sales.

3. High employee turnover

High employee turnover is par for the course in the retail industry: According to 2018 statistics from the National Retail Federation, the turnover rate is around 60 percent, compared to an average of 15 percent for all other industries. This high turnover translates to around $19 billion in HR costs, according to Human Resources Today, and upwards of 230 million days of lost productivity. And that was before the effects of the coronavirus pandemic brought major tumult to the retail employment landscape, with some employers going on major hiring sprees and others implementing furloughs and layoffs. It’s all a recipe for even more turnover as the retail landscape begins to find a new equilibrium in 2021.

But with that new equilibrium comes some new realities for employers. Pay increases and bonuses implemented during the pandemic, as front-line workers faced significant health risks and took on new responsibilities, are likely to remain permanent in some cases. While higher wages will increase retail labor costs for employers, better pay reduces turnover and can generate savings in the long run. “A higher wage, more stable job that keeps people engaged results in better operational outcomes,” Kent Knudson, a partner in Bain & Company’s retail practice, told CNBC. Higher wages aren’t something that can be offset by reducing headcount, either. One of the most likely outcomes of understaffing in an effort to reduce retail labor costs? Poor customer service and its attendant negative consequences. Indeed, competitive compensation and a healthy corporate culture are two of the most important techniques employers like Apple use to reduce turnover while balancing retail labor costs, employee satisfaction and sales targets.

Retail Labor Costs: The Big Picture

Having reliable inventory data, a fully transparent supply chain and an optimized workforce will all help improve the bottom line by reducing time-consuming store walks, providing actionable insights and allowing employees to focus on what will generate the most bang-for-buck. To overcome these in-store challenges, proactive retailers should look to partner with vendors who can provide bespoke technological solutions for any stage of a retailer’s operation.

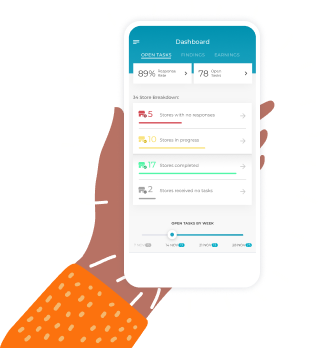

Interesting anecdote: CB4 helps retailers absolve themselves of all of the above. Our AI-powered app helps retailers understand when important products are underselling at any store in near-real time. The immediacy of the solution helps retailers tackle inventory system discrepancies and supply chain inefficiencies that cost them dearly. With fresh actionable recommendations each week, store managers can focus on what’s most critical in their stores, and then get back to serving customers. Watch this short video to learn more here.