Levi Strauss & Co. is rocking and rolling. The 166-year-old retailer (wait, what?) celebrated its 2nd IPO and $8 billion valuation in March, and Levi’s brand recognition is at an all-time high. The iconic red tag is still as ubiquitous and leather patch in back still considered as cool as ever.

Levi’s success isn’t just anecdotal. Having spearheaded Levi’s revival, visionary CEO Chip Bergh is focused on modernization. The retail giant recently announced plans to open about 100 new company-owned stores, just as other apparel sellers in Levi’s cohort, like Abercrombie & Fitch, are shuttering them. The brand recently opened its largest store to date, optimized with the latest and greatest tools (including CB4) from Levi’s technology arsenal.

Here we’ll take a look at the technology that’s helping Bergh deliver on his promise of helping Levi’s become the “leading world-class omni-channel retailer.”

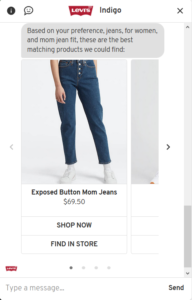

Indigo, an AI-powered Chatbot

In 2019, Marc Rosen, Levi’s EVP and President of Global Direct to Consumer, was named The Robin Report’s Radical of the Year. One of Rosen’s most notable accomplishments was creating Indigo, Levi.com’s chatbot, which the brand uses to converse with shoppers to determine their fit and style needs. His work on Indigo contributed to “11 consecutive quarters of double-digit growth for the direct-to-consumer business,” according to The Robin Report.

Indigo isn’t your average chatbot. It sticks with shoppers while they shop, helping them sift through styles and locate them in-store or online. They can see promotions, trending items, or talk to a customer service agent.

This friendly bot sets a new standard in the world of virtual communication.

Levi’s Technology for Product Innovation

Levi’s isn’t innovating in just the digital world. The new Eureka Lab, nestled blocks from Levi’s San Francisco headquarters, is the brand’s hub devoted to product innovation. Since its inception, the lab has been churning out new products and features that cater to shoppers’ desires.

To date, the Eureka lab has incubated a series of profitable innovations including:

- Four-way stretch denim: Fabric that recovers quickly and doesn’t sag at the knees helped rebound the women’s business and increased sales from less than $800 million to $1 billion annually since 2015.

- Wearable Levi’s technology: Levi’s celebrated the 50th birthday of their iconic trucker jacket with Levi’s Commuter x Jacquard by Google Jacket. The garment, inspired by bike commuters, lets wearers control their iPhones from the jacket’s sleeve. Later, Levi’s optimized the technology for ride sharing, road noise monitoring, and location sharing.

We’ll be watching to see how Levi’s continues to innovate on their product post-IPO.

Levi’s Technology for Supply Chain Enhancements

More than one executive at Levi’s helm is earning industry-wide recognition for outstanding accomplishments. Liz O’Neill, Levi’s Executive Vice President of Product, Innovation, and Supply Chain was named one of Fast Company’s “Most Creative People of 2019.”

“Speed to market and sustainability are two of the biggest challenges in the [apparel] industry,” says O’Neill, who’s headed Levi’s supply chain since 2013. She managed to overcome obstacles to both speed to market and sustainability with Project F.L.X. (short for “future-led execution”).

Project F.L.X. is a game-changing operating model that uses “digital prototyping and lasers to automate the process of applying finishes to jeans”—in other words, making them look distressed, faded, and otherwise cool. Levi’s shares that Project F.L.X. “ushers denim finishing into the digital era” and the brand has shared plan to scale this technology to 50% of the company’s jeans.

This Levi’s technology will help the retailer:

- Replace manual techniques that are time-consuming, labor-intensive, and chemical-reliant, making this stage of the process 20-40x faster.

- Create photo-real finished garments digitally, cutting finishing design and development time in half, improving speed to vendor.

- Capitalize on on-demand and hyper-local production, reducing lead times from months to days.

- Eliminate thousands of chemical formulations, propelling Levi’s goal of achieving zero discharge of hazardous chemicals by 2020.

These are innovations that promise to transform not only Levi’s business but the apparel industry at large.

Levi’s Technology for In-Store Excellence

Levi’s appetite for innovation doesn’t there. The retailer is using the last mile, their brick-and-mortar stores, to transform the customer experience with even more digital advances.

First, Levi’s is investing in customer-facing innovations that take hyper-locality and customization to new heights. The brand’s new 16,902 square-foot Times Square flagship offers every Levi’s collection Levi’s, plus a selection of New York-centric merchandise and a large Authorized Vintage section. The store also features a 500-square expert tailor shop with sewing machines, direct-to-garment printing capabilities, and iPads for customers to browse designs from branded designs from tailors across the globe.

Once shoppers are ready to give garments a try, they’re treated to spacious fittings rooms with Levi’s style advisers just a call button away—typical fitting room woes, not included. The store also has large-format immersive LED screens and mobile POS systems.

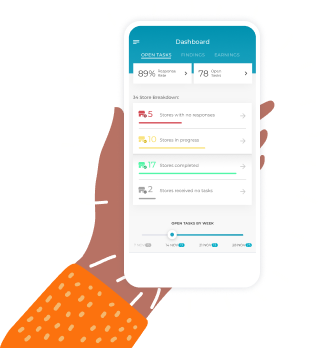

But Levi’s isn’t satisfied roll out the technology red carpet only for shoppers—they’re giving associates next-gen tools to help them serve customers and drive sales. At all US stores, Levi’s is leveraging CB4’s app (and its proprietary AI algorithms) to understand each store’s unique demand patterns. With this tool and others like it, Levi’s enables store teams to provide customers in each market with the products they want most. These efforts help Levi’s ensure a consistently outstanding in-store experience across all stores.

Levi’s isn’t the only major retailer that uses CB4 to drive revenue in stores. Check out this video of Barnes & Noble Chief Digital Officer, Bill Wood, talking about how CB4 has empowered the book seller’s retail workforce.